- Gas Detector

- Gas Monitors

- Gas Analyzer

- Fixed Data Logger Scanner

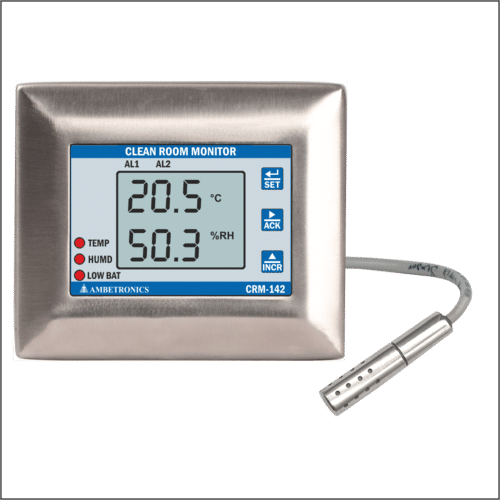

- Clean Room Monitoring Equipment

- Internet Of Things (IoT)

- Temperature Humidity Transmitter

- Digital Stroboscope Tachometer

- Vibration Monitoring Equipments

- Gas Detection System

- Process Control Instruments

- Data Loggers

- Portable Gas Detectors

- Process Indicators

- Gas Alarm

- Calibration Kit

- Data Converters

- IIoT Loggers-Gateways

- Temperature Transmitter

- Sensors

- Gas Leak Detector

- Universal Data Logger

- Gas Leak Alert

DP Clean Room Monitor For Differential Pressure

10500 INR/Piece

Product Details:

- Frame Material Aluminum

- Type Other

- Filter Type Other

- Material Aluminum

- Application Industrial

- Click to view more

X

DP Clean Room Monitor For Differential Pressure Price And Quantity

- 1 Piece

- 10500 INR/Piece

DP Clean Room Monitor For Differential Pressure Product Specifications

- Aluminum

- Other

- Other

- Industrial

- Aluminum

DP Clean Room Monitor For Differential Pressure Trade Information

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cheque

- 1 Week

- Asia Australia South America Western Europe Middle East Central America Eastern Europe North America Africa

- ISO 9001: 2015; CE Certification; CCOE & CMRI Approvals; PESO Tested.

Product Description

The term "DP Clean Room Monitor" is not a standard or widely recognized term in the context of cleanrooms or related industries. It is possible that it refers to a specific product, system, or role, but without additional context, it's challenging to provide a precise answer.

In cleanroom environments, monitoring is crucial to maintain the desired level of cleanliness and control particulate contamination. Cleanrooms are used in industries where even tiny particles or contaminants can adversely affect the production processes or the quality of products, such as semiconductor manufacturing, pharmaceuticals, biotechnology, aerospace, and more.

Some common monitoring systems and equipment in cleanrooms include:

1. Particle Counters: These devices measure and count the number of airborne particles of different sizes within the cleanroom environment.

2. Environmental Sensors: Sensors to monitor and control parameters like temperature, humidity, pressure differentials, and airflow to ensure they meet specific cleanroom standards.

3. Air Filtration Systems: These systems use high-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filters to maintain air cleanliness.

4. Cleanroom Management Software: Software solutions that gather and analyze data from various monitoring systems, allowing facility managers to track cleanroom conditions and take appropriate actions.

5. Cleanroom Garments and PPE: Personnel working within cleanrooms wear specialized garments and personal protective equipment (PPE) to prevent contamination.

Enter Buying Requirement Details

Other Products in 'Clean Room Monitoring Equipment' category

|

AMBETRONICS ENGINEERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese